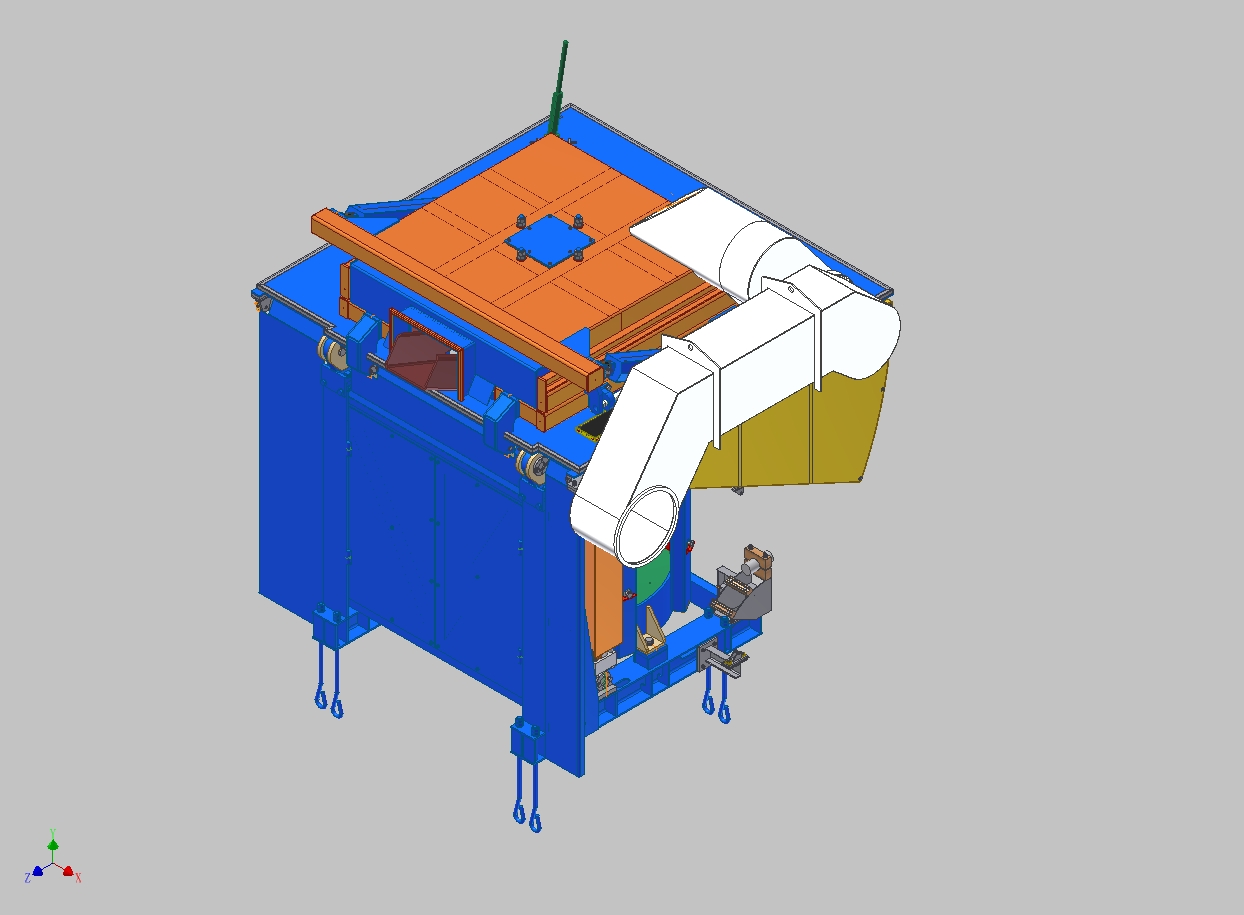

Furnace Assembly with Fume Ring

Depending on customer’s requirement, a weighing system can be installed underneath furnaces and feedback the data of metal weight to PLC at operating panel, and further display on touch panel(HMI), so the weight of the molten metal can be shown on the screen conveniently and straightforwardly, it provides the ease to operators for adjusting composition and arranging production. Automatic melting is also achievable.

Several different style of fume extraction hoods with lid have an ideal effect of energy saving and environmental protection.

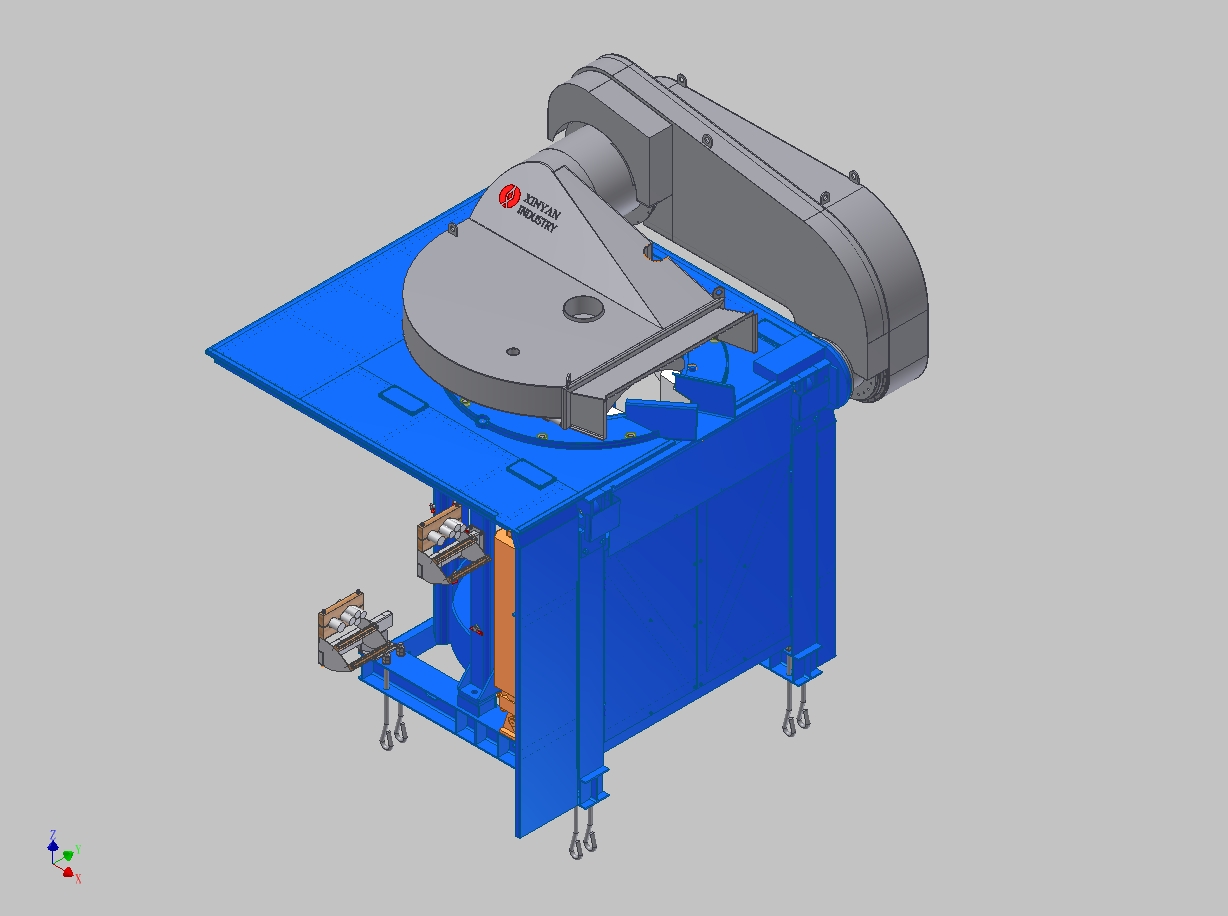

Furnace Assembly with Vortex Fume Hood

Vortex has an optimal extraction effect. The extraction takes place directly at the source of emission.

It has a flat construction, occupies less area. The flat construction is especially advantageous where the transport of liquid iron is carried out by means of ladles hanging from a crane. During the process of pouring, Max tilting angles can be achieved, and the furnace can be emptied completely.

The biggest advantages of vortex fume hood compared with the traditional one is its double-swiveling mode, the body and the channel of the hood can be moved independently. Therefore it not only can tilt backwards and forwards, but also can be put into any optimal position. There is no lock pin needed for tilting direction change. The vortex fume hood avoids the burning heat from lid towards the operators when operator tilts the hood forward. It improves the working environment and reduces the working intensity of operators.

Vortex fume hood can operate at all phases of operation, especially during the treatment of the liquid iron in front of furnace; it can even extract the fume during nodularisation.

Vortex fume hood should be run with enough air flow.

Note:Vortex fume hood will be damaged if running with no air flow or not enough air flow.

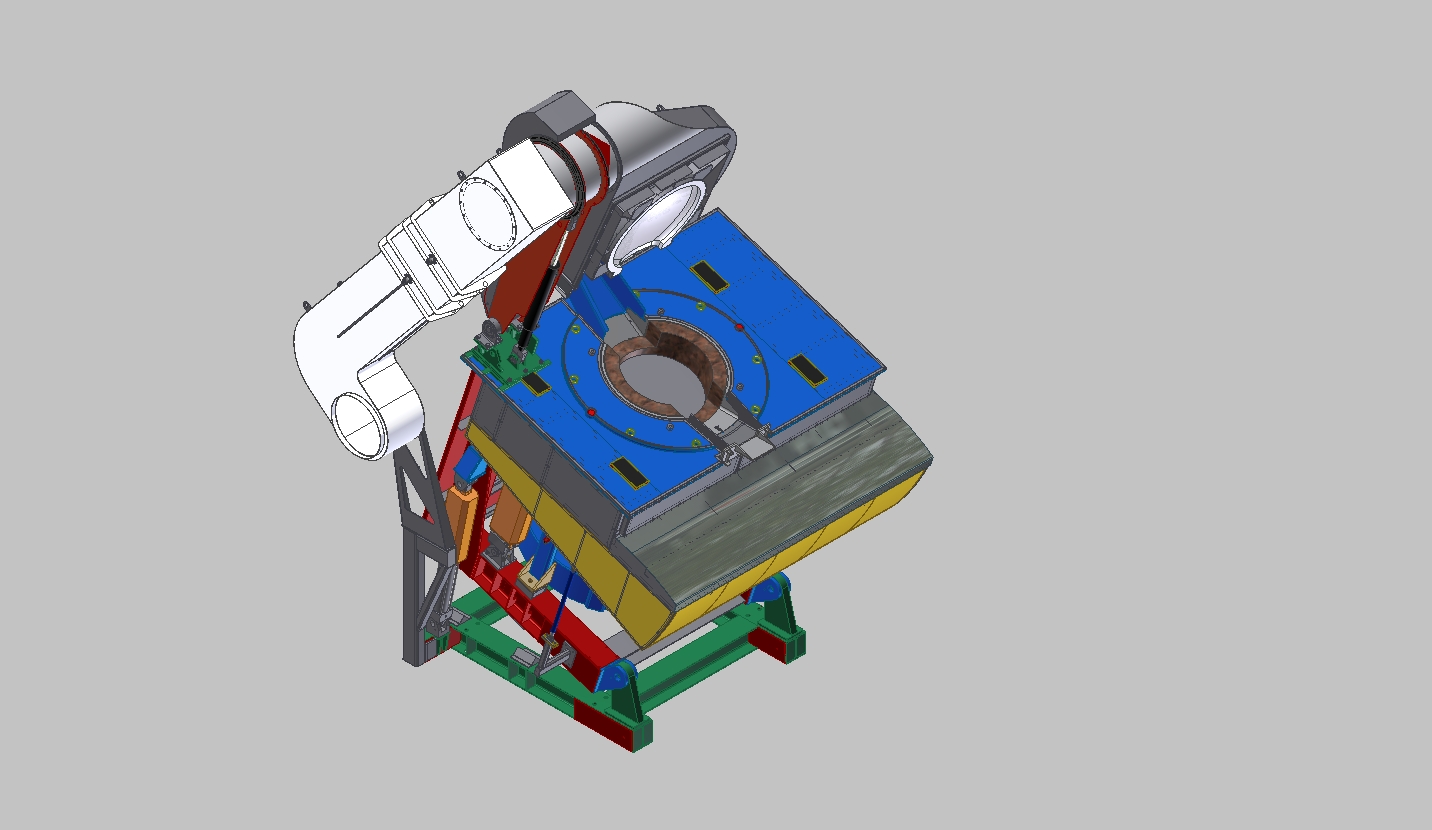

Furnace Assembly with Traditional Fume Hood

Fume hood is operated by hydraulic cylinders to open backwards and forwards. It has a strong steel structure design, refractory rammed lid is installed at the middle of hood. The lilting direction is decided by moving the lock pin to the different locations.

Fume hood is closed during the melting process lid covers the molten bath, it minimizes the heat loss when charging, melting and pouring, meanwhile it extracts the fume and dust by sufficient air flow, to meet discharge standard or improve the result.

The fume hood opens backwards and forwards and connects to the fume discharge piping system by the flange connection located at the same axis as furnace tilting pivot.

Furnace charging can be done, when hood opens forwards.

When hood opens backwards, lining can be pushed out and spout area can be maintained and repaired.

Traditional fume hood should be run with enough air flow.

Note:Fume hood will be damaged if running with no air flow or not enough air flow.

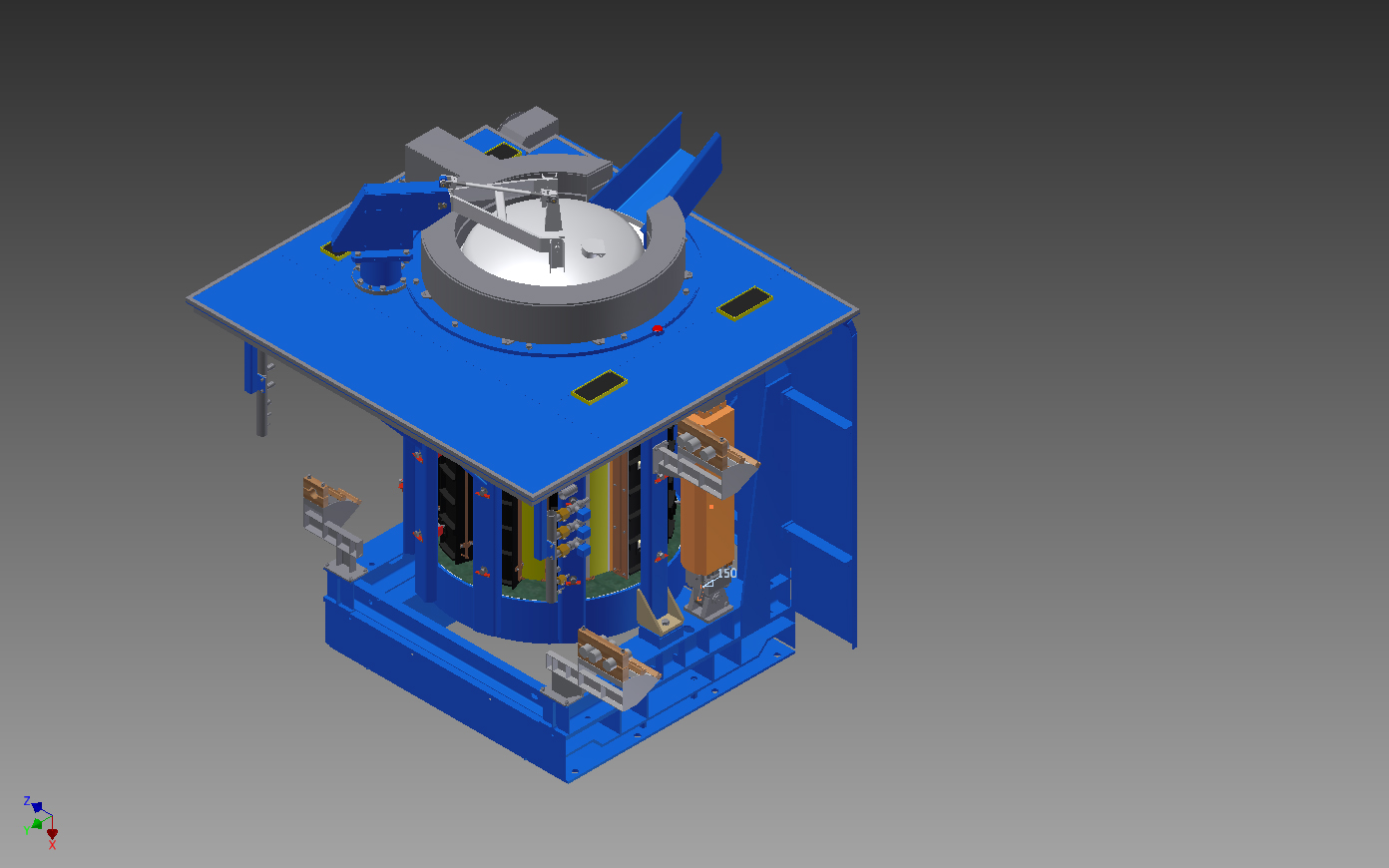

Furnace Assembly with Back Tilt Mechanism for Deslagging

Furnace back tilt mechanism, which can tilt furnace backwards, makes deslagging possible at the back side of furnace platform. It has the following advantages.

1、It further reduces the working intensity of furnace operator;

2、This mechanism improves working efficiency and makes operators safer when they are doing deslagging;

3、Combined with vortex fume hood, it is more environmental when deslging is operated.

This mechanism can tilt the furnace backwards within the range of 0-18°,it adjusts furnace back tilt angle to any required value according to molten metal height inside furnace .As a result, molten metal and deslagging spout are at the same horizontal level, which makes deslagging more convenient and effortless. Deslagging spout can be replaced quickly and easily. Meanwhile furnace rear platform has a unique curved design, which makes minimum gap between furnace rear platform and concrete foundation ,so foundry debris falling into furnace pit through the gap can be prevented to the maximum extent.